The automatic, precise, useful and just the right tool for some photogrammetry jobs

As a professional surveyor with my own company, I was recently asked by a business contact - Why did you buy a cheap bulders level as your first tool?

The answer is simple: using the right tool is critical in ensuring that a survey job is carried out with the precision to comply with project specifications.

Using the wrong tool can result in costly resurveys, which can take a toll on the contractor's reputation and bottom line.

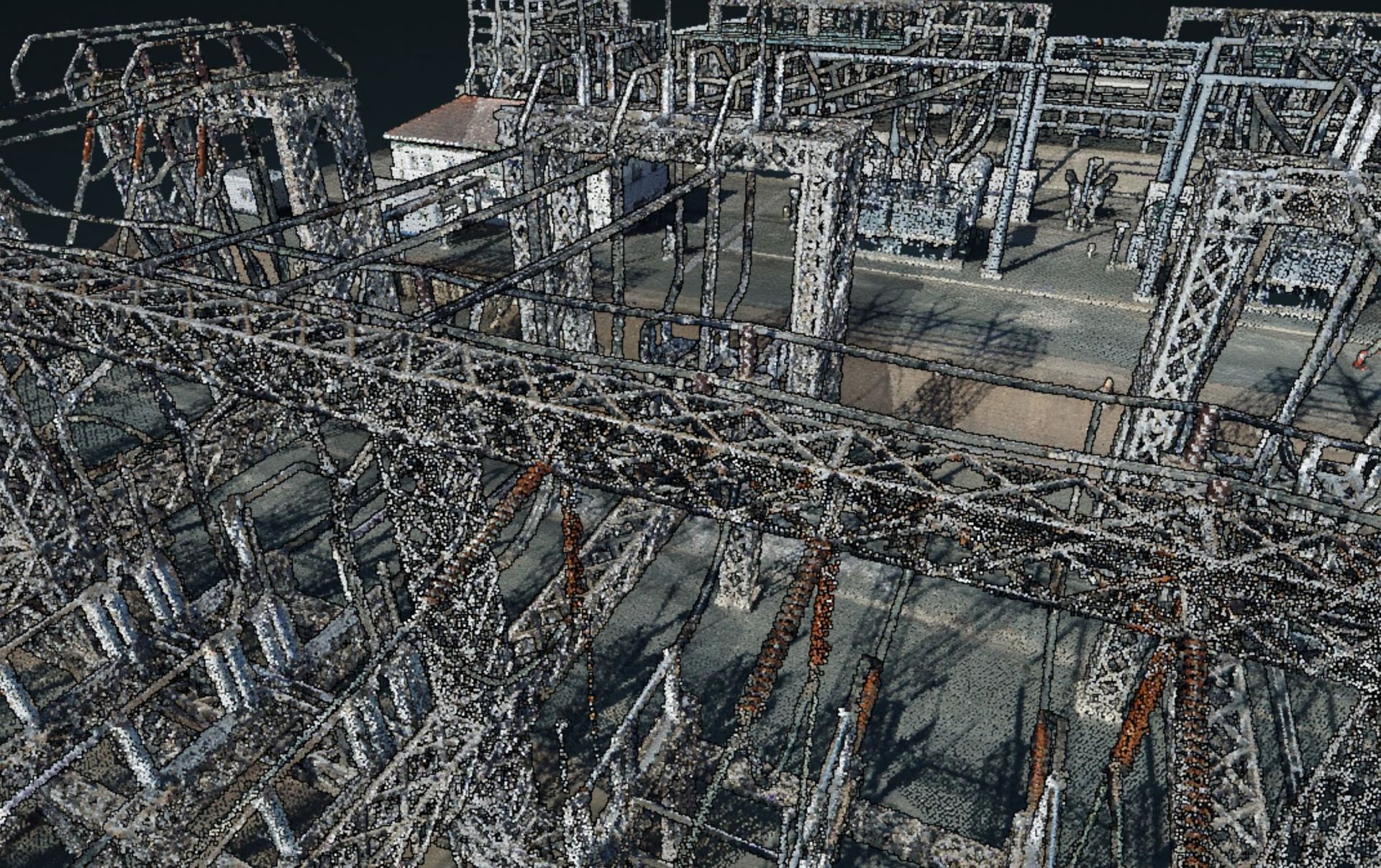

For example, many surveying companies make money by conducting small photogrammetric surveys for earthworks, construction progress, planning, and other medium-precision tasks that fall within RICS Accuracy Bands E and F. These bands provide a useful shorthand for clients to ensure that the data delivered is fit for purpose.

When conducting a survey, it's best to use a control method for both horizontal and vertical measurements that is twice the precision requested by the client for the entire project.

While it's possible to use a quality camera and high GSD to gain a precision photogrammetry solution for the entire project that meets RICS band C or D, gaining vertical control accuracy from the commonly used satellite positioning method Real Time Kinematic or RTK is simply not possible.

In situations where the relative Z precision of a photogrammetry survey is critical, and any mistake could result in costly resurveys and hard conversations with the client down the line, is where level comes in!

While it may seem outdated, a reliable level can play a vital role in high-tech surveying by updating the Z values of RTK'd points.

For instance, the Bosch GOL 26D Automatic level, which with staff and tripod is available from Screwfix for under 300 GBP, can measure individual levels to 1.6mm precision, and can help calculate the relative between the control points for a decent-sized photogrammetric survey to within 5mm in just a few hours.

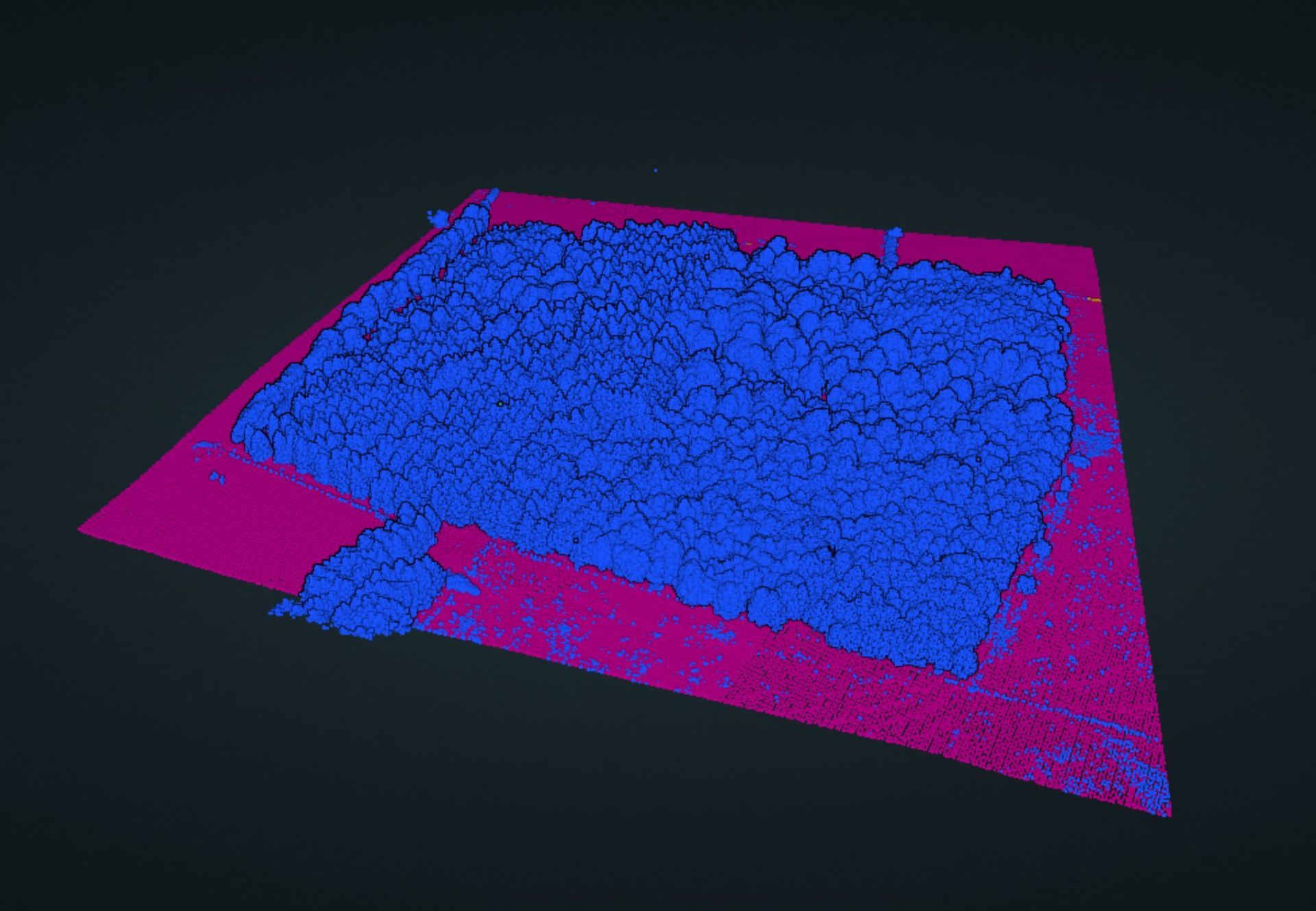

This process, known as "levelling," "levelling runs," or "levelling loops," ensures that the Z values are as precise as the XY, avoiding any out-of-tolerance discrepancies between the digital surface model and the real-world terrain.

To apply this in the field, you will need to buy the automatic level, find a reliable "chain man," and have them hold the staff on nails, or other "well-defined features" placed at strategic locations around your site. With a windless day, and a competent operator and chainman, you can finish a field, construction site, or aggregates yard in an afternoon.

Once you have this control collected, you can process the photogrammetry as normal and replace the Z values from levelling from those gained from RTK. This would then give you XY values to a 20mm precision but Z values to a 5mm precision this then meets the specification for RICS band D.

These higher precision surveys can then be used to meet the clients higher standards without the need to employ a laser scanner or total station both of which have a significantly higher cost to the survey company even if rented for the task.

Using the right tool for the job can ultimately save time and money while producing more precise, higher-value, and useful data.

So next time you are tempted to run out and buy an expensive tool remember tried and tested methods may be implemented at a lower cost.